-

Buy Now

-

Help & Guides

- Our Work

-

Contact Us

-

About Us

+Categories

- 24v Festoon Bulbs

- Accessories

- Christmas

- Colour Temperature

- Commercial Grade Lighting

- Cool White

- Custom Made Neon Lights

- Dot Less Strip

- Fairy Lights

- Festoon

- Festoon Lighting

- Flexible Neon

- Flexible Neon Signs

- Floodlights

- Kelvins

- Led Floodlights

- Led Strip

- Modules

- Neon Led Strip

- Outdoor Festoon Lighting

- Pure White

- Tree Lighting

- WAGO

- Warm White

- White

- Wiring

The Advantages of Commercial Lighting

Discover the advantages of commercial lighting with Flexible Neon's offerings. Explore the longevity, energy efficiency, and aesthetic appeal of festoon lighting, LED floodlights, fairy lights, and LED modules for your projects.

Choosing the Right Christmas Lights: A Complete Guide by Flexible Neon

Why Choose Flexible Neon's Low-Voltage Lighting Solutions for Safety and Style

Creative Lighting Ideas for Restaurants and Cafés: Elevate Your Ambiance with Flexible Neon

Creating Year-Round Ambience with Warm White Fairy Lights

Understanding Lumens: A Comprehensive Guide for Choosing the Right Lighting

Fairy Lights for Commercial Use: Creating Magical Ambiences in Business Settings

Why Choose Extra Low Voltage Lighting for Your Business?

Embracing extra low voltage lighting within your business not only signifies a technological advancement but also embodies a strategic choice laden with a multitude of benefits. One of the foremost advantages lies in the heightened safety offered by low voltage systems. By inherently reducing electrical risks, these systems create a secure environment conducive to the well-being of both employees and customers. This is particularly true for establishments equipped with our collections, which include 12V, 24V, and 36V lighting solutions, ensuring enhanced safety across diverse business landscapes, from corporate offices to bustling retail hubs.

Furthermore, extra low voltage lighting seamlessly aligns with contemporary sustainability goals. Engineered for maximum energy efficiency, our 12V, 24V, and 36V lighting systems curtail overall energy consumption, leading to tangible reductions in operational expenditures. This not only contributes to lower costs but also positions your business as a champion of environmental stewardship. By opting for our eco-friendly lighting solutions, you demonstrate a commitment to sustainable practices, bolstering your brand reputation as a responsible custodian of the planet.

In an era where environmental consciousness is paramount, businesses that embrace our extra low voltage lighting solutions take a definitive stride towards a luminous, safer, and greener future. By prioritising safety, energy efficiency, and sustainability, you're not only illuminating your spaces but also setting a precedent for responsible and forward-thinking operational paradigms.

Connecting Low Voltage Wires to Flexible Neon Product

Connecting low voltage wires together is a common task when working with lighting systems like festoon cables, LED drivers, dotless strips, modules, flexible neon, and more. Follow this detailed guide to ensure safe and reliable connections for your low voltage lighting projects.

Materials You Will Need:

- Low voltage wires (such as festoon cable, dotless strip wires, module wires, or flexible neon wires).

- Wire cutters/strippers.

- Soldering iron and solder (for permanent connections, if needed).

- Heat shrink tubing (for added insulation and protection).

- Wire connectors (such as wire nuts, butt connectors, or crimp connectors).

- Electrical tape (as an alternative to heat shrink tubing).

- Cable ties (for cable management).

- Heat gun or lighter (if using heat shrink tubing).

- Safety gear: Safety goggles and heat-resistant gloves.

Procedure:

1. Safety First:

- Always work in a well-ventilated area.

- Wear safety goggles and heat-resistant gloves to protect your eyes and hands.

2. Prepare the Wires:

- Ensure that the low voltage wires you plan to connect are clean, undamaged, and stripped of any damaged insulation.

- Strip the ends of the wires to expose approximately 1/4 to 1/2 inch (6-12 mm) of bare wire. Use wire strippers to do this.

3. Choose the Connection Method:

Wire Connectors (WAGO):

- Wire connectors are a quick and reliable way to connect low voltage wires together. They come in various sizes to accommodate different wire gauges.

- To use wire connectors:

- Insert the prepared wires into the open slots of the WAGO connector. Make sure that each wire goes into its designated slot based on size and polarity.

- Once the wires are inserted correctly, close the clamping unit securely. This action will grip the wires tightly, establishing a secure connection.

- Ensure that the wires are held firmly in place by gently tugging on them.

Soldering (for Permanent Connections):

- Soldering provides a strong and secure connection. This method is ideal for applications where you don't want any chance of wires coming loose.

- To solder wires together:

- Twist the exposed ends of the wires together.

- Heat your soldering iron to the appropriate temperature for your solder.

- Apply the soldering iron to the twisted wires to heat them.

- Apply solder to the heated wires, allowing it to flow evenly over the twisted area.

- Remove the soldering iron and let the solder cool and solidify. Ensure the wires are held in place until the solder hardens.

- Optionally, slide heat shrink tubing over the soldered area and use a heat gun or lighter to shrink it for added protection.

4. Insulate the Connection:

- If using wire connectors, they provide built-in insulation.

- If soldering, slide heat shrink tubing over the soldered area or use electrical tape to insulate the connection.

- If using heat shrink tubing, apply heat evenly using a heat gun or lighter until the tubing shrinks and seals the connection tightly. Ensure there are no gaps in the tubing.

5. Secure and Organise the Wires:

- Use cable ties or clips to secure and organise the connected wires, keeping them neat and tidy.

6. Test the Connection:

- Before energising your lighting system, test the connection to ensure it's secure and functioning correctly.

7. Repeat as Needed:

- Repeat the above steps for all the low voltage wire connections in your project.

By following these steps, you can safely and effectively connect low voltage wires for your festoon cables, dotless strips, modules, flexible neon, and other low voltage lighting applications. Always adhere to safety guidelines and manufacturer recommendations for your specific lighting products.

Choosing the Right Wire Gauge for Flexible Neon Lighting Applications

Choosing the correct wire gauge for flexible neon lighting is essential for safety and efficiency. It is important to consider the current load and voltage drop to achieve optimal performance. Various American Wire Gauge (AWG) options are available to meet the specific needs of different lighting applications.

Understanding the Longevity of Flexible Neon LED Strip Lights

LED strip lights, like those offered by Flexible Neon, are renowned for their longevity and versatility. To understand how long these LED strip lights can last, it's essential to examine their structure and the factors that influence their lifespan.

The Structure of LED Strip Lights:

The main components of LED strips include LED's (Light Emitting Diodes), FPCB (Flexible Printed Circuit Boards), resistors, and other essential elements. These components are assembled using Surface Mount Technology (SMT) Assembly Process, which mounts LED's, resistors, and other components onto the FPCB.

Some outdoor or underwater LED strips may also have a protective silicone or PU glue coating. However, it's crucial to note that LED strips with higher IP ratings, designed for enhanced protection against dust and water, may have a somewhat shorter lifespan compared to IP20-rated LED strips. This is primarily because LED strips with higher IP ratings struggle to dissipate heat as efficiently. Generally, cooler environments support a longer LED lifespan, as higher temperatures tend to reduce light output. (For more details on how heat affects LED's, see "How are LED's affected by heat?")

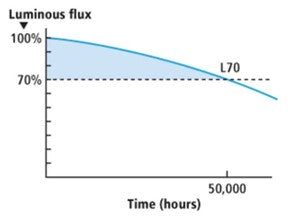

Understanding LED Lifetime and the "L70" Rule:

Unlike traditional incandescent or fluorescent bulbs that fail abruptly, LED's gradually lose their light output over time. They continue working until they become too dim to be practical. The industry has established a standard for this gradual decrease in light output, known as the "L70" metric. It signifies the point at which an LED has dimmed to 70% of its original brightness.

In some instances, you may come across symbols like "LxByCz(h)" to describe the lifetime of LED luminaires. Here's what it means:

- "Lx" denotes the number of hours after which the luminous flux has dropped to x percent.

- "By" signifies the percentage of luminaires in the same group that have fallen below the specified luminous flux.

- "Cz" indicates the percentage of luminaires in the group that have experienced total LED failure.

For example, "L70B10C0.1 (50,000 h)" means that after 50,000 hours:

- The LED luminaires must still provide at least 70% of their initial luminous flux.

- Up to 10% of the luminaires can provide less than 70% of the initial luminous flux.

- In just 0.1% of the luminaires, all LED's may have failed.

How Is "L70" Calculated?

To calculate LED lifetime, a testing method called LM-80 is often employed. This method specifies a predetermined temperature and driving current for testing LED samples. The light output change is measured at intervals of 1000 hours, up to a maximum of 10,000 hours. Reputable manufacturers conduct LM-80 testing at third-party laboratories to ensure impartial results. They then publish these results in report format. It's important to note that reliable LED strip suppliers should be able to provide LM80 test reports, especially when purchasing large quantities.

However, LED life testing can be time-consuming. For instance, even with LED's operating 24/7, a 10,000-hour test takes around 14 months. This timeframe is impractical for fast-moving industries like LED lighting. To address this issue, the TM-21 extrapolation algorithm is employed. It considers the performance of LM-80-tested samples during the first few thousand hours and provides an estimated lifetime.

Factors Affecting LED Strip Light Lifespan:

Several factors can affect the lifespan of LED strip lights:

-

FPCB (Flexible Printed Circuit Board): High-quality, double-layer pure copper flexible PCBs facilitate the smooth passage of significant current, reduce heat generation, and promote efficient heat dissipation. By attaching the LED strip to an aluminium profile, you can dissipate heat effectively and lower the operating temperature, thus extending LED life.

-

Double-Sided Tape: Quality matters when it comes to adhesive tape. LED strip lights from reputable suppliers often use high-quality tapes, like the 3M brand VHB tape. Proper tape quality ensures long-lasting installations and good thermal conductivity.

-

Resistors: Resistors regulate the forward current through LED's to maintain their designed brightness. It's crucial to use high-quality resistors from reputable manufacturers to avoid shortening the LED strip's life or causing damage.

-

Power Supply: The power supply is a critical component. Always use a reliable, brand-name power supply to ensure stable voltage output. Low-quality power supplies can deliver unstable voltages that might exceed the LED strip's working voltage, potentially damaging it.

-

Heat Dissipation: Heat can significantly reduce LED lifespan. To manage heat effectively, install LED strips in well-ventilated areas. If feasible, attach the LED strip to an aluminium profile to aid in heat dissipation, as aluminium is an excellent conductor of heat.

By considering these factors and following best practices for installation and maintenance, you can maximise the lifespan of your Flexible Neon LED strip lights, ensuring they provide brilliant and reliable illumination for years to come.

Connecting Wires Using Soldering and WAGO Connectors with Polarity Match

Whether you're working on electrical projects or crafting intricate setups, knowing how to properly connect wires is essential for safety and efficiency. In this detailed guide, we'll walk you through two common methods: soldering and using Wago connectors. We'll also emphasise the importance of maintaining consistent wire polarity to ensure your connections work seamlessly.

Materials You'll Need:

- Wires to be connected

- Soldering iron and solder (if soldering)

- Wago connectors (if using)

- Wire stripper or cutter

- Dual Adhesive Heat shrink tubing (if soldering)

- Electrical tape (if using)

- Multimeter (for polarity verification)

Method 1: Soldering Wires

Step 1: Prepare the Wires

- Strip about 1 cm of insulation from each wire using a wire stripper.

- Twist the exposed wire strands to prevent fraying.

- For safety, we recommend the wires are feathered to ensure the opposing wires do not touch.

Step 2: Solder the Wires

- Heat your soldering iron and apply a small amount of solder to the tip.

- Hold the wires together with their stripped ends aligned.

- Touch the soldering iron's tip to the wires, allowing the heat to melt the solder and create a strong bond between the wires.

Step 3: Insulate with Heat Shrink Tubing (This step can be done before step 2 to make a more streamlined connection)

- Slide a piece of heat shrink tubing over the soldered area.

- Use a heat gun to shrink the tubing, providing insulation and protection to the solder joint.

Method 2: Using Wago Connectors

Step 1: Prepare the Wires

- Strip about 1 cm of insulation from each wire.

- Insert the stripped wires into the appropriate Wago connector slots (same polarities). Ensure each wire is securely inserted.

Step 2: Secure the Wires

- Press down on the orange lever of the Wago connector. This will securely clamp the wires in place.

Step 3: Verify Polarity

- Use a multimeter to verify that the wire polarity is consistent between the connections.

- Connect the multimeter probes to the corresponding wires to ensure positive (+) and negative (-) match.

General Tips:

- Weatherproofing: Employing electrical tape is an effective method for swiftly safeguarding your connection against environmental factors. Exercise caution, as any openings can pose potential hazards.

-

Maintain Consistent Polarity: To prevent electrical issues, ensure that the wires' polarity (positive and negative) matches correctly when connecting them. A reversed polarity can lead to equipment damage or malfunction.

-

Safety First: Always work in a well-ventilated area, and take necessary precautions to avoid burns when soldering. If using Wago connectors, handle them carefully to prevent any accidental damage.

-

Practice Good Wire Management: Keep the wire connections tidy by using cable ties, conduit, or other wire management solutions.

-

Test Your Connections: Before finalising your project, test the connected wires using appropriate electrical equipment to verify that the connections are functioning as intended.

-

Wear Safety Gear: When soldering, protect your hands with gloves and your eyes with safety goggles to prevent accidental burns or splashes.

By following this guide, you'll be able to confidently and safely connect wires using both soldering and Wago connectors while maintaining proper polarity. This skill will prove invaluable for a wide range of electrical and DIY projects.

Illuminating Trees with Festoon Lighting

Why We Prefer Warm White

At Flexible Neon, we prefer warm white lighting for several compelling reasons. Warm white light offers a softer, more natural glow that closely resembles traditional incandescent lighting, creating a welcoming and cosy ambience in any space. Here are some key reasons why warm white is our top choice:

-

Comfort and Relaxation: Warm white light has a colour temperature typically ranging from 2700K to 3500K, which emits a gentle, calming glow that promotes relaxation. It's ideal for areas where people gather, such as living rooms, bedrooms, and dining spaces.

-

Enhancing Decor: Warm white light complements various interior designs and colour schemes, enhancing the aesthetic appeal of your space. It creates a harmonious atmosphere that suits both modern and classic settings.

-

Aesthetic Appeal: Warm white light is often preferred for its flattering effect on skin tones, making it an excellent choice for retail and hospitality spaces, as well as photography studios.

-

Cosy Ambience: Whether it's in a restaurant, café, or residential setting, warm white lighting helps to create a cosy and inviting environment that encourages social interaction and relaxation.

-

Versatility: Warm white lighting is incredibly versatile and can be used in various applications, such as accent lighting, cove lighting, or general room illumination.

-

Well-Being: Warm white light has been associated with improved mood and overall well-being. It is considered more soothing and less disruptive to circadian rhythms than cool white or daylight lighting.

-

Subtle and Stylish: Warm white light adds a touch of elegance and sophistication to any space, making it an excellent choice for creating a warm and inviting atmosphere.

At Flexible Neon, we prioritise the well-being and satisfaction of our customers. We believe that warm white lighting enhances the overall experience and comfort in any environment, making it a preferred option for a wide range of lighting projects. With our extensive collection of warm white LED products, we are committed to helping you achieve the perfect lighting solution that meets your specific needs and preferences.

- FAQs

- Gallery

- Contact Us

- T&Cs

- Delivery

- International Shipping

- Refunds Policy

- Privacy Policy

- Buy now

- Guides

Sign up to get the latest on sales, new releases and more…

© 2026 Flexible Neon.