-

Buy Now

-

Help & Guides

- Our Work

-

Contact Us

-

About Us

+Categories

- 24v Festoon Bulbs

- Accessories

- Christmas

- Colour Temperature

- Commercial Grade Lighting

- Cool White

- Custom Made Neon Lights

- Dot Less Strip

- Fairy Lights

- Festoon

- Festoon Lighting

- Flexible Neon

- Flexible Neon Signs

- Floodlights

- Kelvins

- Led Floodlights

- Led Strip

- Modules

- Neon Led Strip

- Outdoor Festoon Lighting

- Pure White

- Tree Lighting

- WAGO

- Warm White

- White

- Wiring

The Advantages of Commercial Lighting

Discover the advantages of commercial lighting with Flexible Neon's offerings. Explore the longevity, energy efficiency, and aesthetic appeal of festoon lighting, LED floodlights, fairy lights, and LED modules for your projects.

Illuminate Your Imagination: The Flexible Neon Revolution

Choosing the Right Christmas Lights: A Complete Guide by Flexible Neon

Why Choose Flexible Neon's Low-Voltage Lighting Solutions for Safety and Style

Creative Lighting Ideas for Restaurants and Cafés: Elevate Your Ambiance with Flexible Neon

Top 5 Commercial Applications of Neon LED Strips

How to Install Neon LED Strips: Step-by-Step Tutorial

Installing Neon LED strips is an excellent way to bring a vibrant and modern look to your space, whether it's for commercial signage, architectural highlights, or creative lighting designs. At Flexible Neon, we offer a range of high-quality neon LED strips in various sizes and styles, including 6x12mm, 8x16mm, 8x10x16mm, 10x13x22mm, and 15x13mm. With the right tools and preparation, installing these neon LED strips is a straightforward process. In this step-by-step guide, we'll cover different mounting surfaces, installation methods, wiring instructions, and essential safety tips. Plus, we'll showcase the variety of mounting clips and channels we offer to make your installation as seamless as possible.

Understanding Lumens: A Comprehensive Guide for Choosing the Right Lighting

Enhance Your Retail Space with Neon LED Strips: A Guide for Business Owners

Neon LED Strips vs. Traditional Neon Lights: Which is Better?

The Science Behind Neon LED Strips: How Do They Work?

Future Trends in Neon LED Strip Lighting

Neon LED strip lighting has come a long way, evolving from simple decorative elements to versatile, high-tech solutions that transform spaces both aesthetically and functionally. As technology continues to advance, the future of neon LED strip lighting is set to introduce even more innovative trends and designs. In this blog, we'll explore the upcoming trends in neon LED strip technology and how these advancements will influence home and commercial lighting in the future. We’ll also highlight how Flexible Neon's extensive product range is at the forefront of these exciting developments.

Creating Impactful Storefront Displays with Neon LED Strips

Custom Made Neon Lights: Boosting Your Brand's Visual Appeal

Why Choose Extra Low Voltage Lighting for Your Business?

Embracing extra low voltage lighting within your business not only signifies a technological advancement but also embodies a strategic choice laden with a multitude of benefits. One of the foremost advantages lies in the heightened safety offered by low voltage systems. By inherently reducing electrical risks, these systems create a secure environment conducive to the well-being of both employees and customers. This is particularly true for establishments equipped with our collections, which include 12V, 24V, and 36V lighting solutions, ensuring enhanced safety across diverse business landscapes, from corporate offices to bustling retail hubs.

Furthermore, extra low voltage lighting seamlessly aligns with contemporary sustainability goals. Engineered for maximum energy efficiency, our 12V, 24V, and 36V lighting systems curtail overall energy consumption, leading to tangible reductions in operational expenditures. This not only contributes to lower costs but also positions your business as a champion of environmental stewardship. By opting for our eco-friendly lighting solutions, you demonstrate a commitment to sustainable practices, bolstering your brand reputation as a responsible custodian of the planet.

In an era where environmental consciousness is paramount, businesses that embrace our extra low voltage lighting solutions take a definitive stride towards a luminous, safer, and greener future. By prioritising safety, energy efficiency, and sustainability, you're not only illuminating your spaces but also setting a precedent for responsible and forward-thinking operational paradigms.

Buy Flexible Neon

In the realm of architectural lighting and beyond, the captivating glow of neon is unparalleled. At Flexible Neon, we offer a diverse range of neon options tailored to elevate any space or project, from architectural lighting to sign making and accent lighting. Let's delve into the various options we provide and explore the myriad of versatile uses for each.

-

6x12mm Neon Flex: The slender and discreet 6x12mm Neon Flex is ideal for creating stunning signage. Its compact size allows for intricate detailing, making it a popular choice for custom neon signs that command attention and convey messages with flair.

-

8x16mm Neon Flex: For those seeking to make a bold statement, the 8x16mm Neon Flex offers a wider profile suitable for both architectural lighting and accentuating signage. Its flexibility makes it easy to shape and mould, allowing for creative applications in various indoor and outdoor settings.

-

8x10x16mm Neon Flex: Designed for durability and versatility, the 8x10x16mm Neon Flex is not only resilient enough for outdoor installations but also perfect for accent lighting in interior spaces. Its robust construction makes it a reliable choice for architectural lighting fixtures, while its vibrant glow adds ambience and visual interest to any environment.

-

10x12x22mm Neon Flex: With its larger profile and maximum impact, the 10x12x22mm Neon Flex is perfect for creating eye-catching signage that demands attention. Its versatility extends beyond signage to accent lighting, where it can be used to highlight architectural features, create focal points, or set the mood in any space.

-

13x15mm Neon Flex: The 13x15mm Neon Flex strikes a balance between size and flexibility, making it suitable for a wide range of applications. Whether used for accent lighting or decorative installations, its versatility knows no bounds, allowing for endless creative expression.

At Flexible Neon, we pride ourselves on delivering customisable neon solutions tailored to your specific needs. Whether you're looking to enhance a commercial space, create captivating signage, or add ambience to a residential interior, our team of experts is dedicated to helping you bring your vision to life.

With our commitment to quality, versatility, and innovation, Flexible Neon is your go-to destination for all your neon lighting needs. Explore our extensive range of options and discover the transformative power of neon in architectural design, signage, and accent lighting. Experience the beauty of neon and elevate your space with Flexible Neon today.

Benefits of Investing in Flexible Neon Signs For Your Business

- Enhanced Visibility: With their vibrant colours and captivating glow, flexible neon signs stand out, drawing attention to your business even in a crowded market. Their luminous display ensures high visibility, making your establishment impossible to miss, especially during nighttime.

Tip: Flexible neon signs are particularly effective for businesses aiming to make a bold statement or establish a unique brand identity.

-

Unlimited Customisation: The flexibility of flexible neon allows for endless customisation possibilities. Whether you desire intricate designs, unique shapes, or personalised messages, flexible neon signs can be tailored to suit your brand's aesthetics and marketing objectives.

-

Nighttime Appeal: Unlike traditional signage that may fade into the darkness after sunset, flexible neon signs shine brightly, ensuring your business remains visible and inviting, even after hours. Their vibrant illumination creates an inviting ambience, enticing potential customers to explore further.

-

Energy Efficiency: Despite their luminous presence, flexible neon signs are surprisingly energy-efficient. Compared to conventional signage options, they consume minimal electricity, resulting in cost savings on both installation and operational expenses. Plus, utilising extra low voltage (12V) technology ensures safety while reducing energy consumption.

-

Longevity and Durability: Built to withstand the elements and the test of time, flexible neon signs boast impressive longevity. With proper installation and maintenance, they can last up to 12 years or more (depending on LED Lifespan usage and other factors), ensuring a durable and reliable signage solution for your business.

-

Consumer Appeal: With a rich history in advertising, neon signs have ingrained themselves in consumer consciousness. About 68 percent of participants in a survey said they bought a product or service simply because a neon sign caught their eye. Furthermore, a study by FedEx Office found that nearly 76% of consumers enter a store they have never visited before based purely on its signs. This demonstrates the incredible allure and consumer appeal of neon signage, making it an effective tool for attracting foot traffic and increasing brand awareness.

Install a Flexible Neon Sign & Illuminate Your Business With Style At Flexible Neon, we specialise in crafting high-quality flexible neon signs that elevate your brand presence and captivate your audience. Our experienced team ensures seamless installation, allowing you to reap the benefits of flexible neon signage immediately. Stand out from the competition and make a lasting impression with a custom flexible neon sign from Flexible Neon.

Connecting Low Voltage Wires to Flexible Neon Product

Connecting low voltage wires together is a common task when working with lighting systems like festoon cables, LED drivers, dotless strips, modules, flexible neon, and more. Follow this detailed guide to ensure safe and reliable connections for your low voltage lighting projects.

Materials You Will Need:

- Low voltage wires (such as festoon cable, dotless strip wires, module wires, or flexible neon wires).

- Wire cutters/strippers.

- Soldering iron and solder (for permanent connections, if needed).

- Heat shrink tubing (for added insulation and protection).

- Wire connectors (such as wire nuts, butt connectors, or crimp connectors).

- Electrical tape (as an alternative to heat shrink tubing).

- Cable ties (for cable management).

- Heat gun or lighter (if using heat shrink tubing).

- Safety gear: Safety goggles and heat-resistant gloves.

Procedure:

1. Safety First:

- Always work in a well-ventilated area.

- Wear safety goggles and heat-resistant gloves to protect your eyes and hands.

2. Prepare the Wires:

- Ensure that the low voltage wires you plan to connect are clean, undamaged, and stripped of any damaged insulation.

- Strip the ends of the wires to expose approximately 1/4 to 1/2 inch (6-12 mm) of bare wire. Use wire strippers to do this.

3. Choose the Connection Method:

Wire Connectors (WAGO):

- Wire connectors are a quick and reliable way to connect low voltage wires together. They come in various sizes to accommodate different wire gauges.

- To use wire connectors:

- Insert the prepared wires into the open slots of the WAGO connector. Make sure that each wire goes into its designated slot based on size and polarity.

- Once the wires are inserted correctly, close the clamping unit securely. This action will grip the wires tightly, establishing a secure connection.

- Ensure that the wires are held firmly in place by gently tugging on them.

Soldering (for Permanent Connections):

- Soldering provides a strong and secure connection. This method is ideal for applications where you don't want any chance of wires coming loose.

- To solder wires together:

- Twist the exposed ends of the wires together.

- Heat your soldering iron to the appropriate temperature for your solder.

- Apply the soldering iron to the twisted wires to heat them.

- Apply solder to the heated wires, allowing it to flow evenly over the twisted area.

- Remove the soldering iron and let the solder cool and solidify. Ensure the wires are held in place until the solder hardens.

- Optionally, slide heat shrink tubing over the soldered area and use a heat gun or lighter to shrink it for added protection.

4. Insulate the Connection:

- If using wire connectors, they provide built-in insulation.

- If soldering, slide heat shrink tubing over the soldered area or use electrical tape to insulate the connection.

- If using heat shrink tubing, apply heat evenly using a heat gun or lighter until the tubing shrinks and seals the connection tightly. Ensure there are no gaps in the tubing.

5. Secure and Organise the Wires:

- Use cable ties or clips to secure and organise the connected wires, keeping them neat and tidy.

6. Test the Connection:

- Before energising your lighting system, test the connection to ensure it's secure and functioning correctly.

7. Repeat as Needed:

- Repeat the above steps for all the low voltage wire connections in your project.

By following these steps, you can safely and effectively connect low voltage wires for your festoon cables, dotless strips, modules, flexible neon, and other low voltage lighting applications. Always adhere to safety guidelines and manufacturer recommendations for your specific lighting products.

How To Solder Flexible Neon (12V)

Soldering Flexible Neon (12V) can be a precise process, but with the right tools and technique, it can be accomplished effectively. Here's a detailed guide on how to solder Flexible Neon for single-colour, RGB, and pixel applications:

Note: Before you begin, make sure you have the appropriate safety gear, such as safety goggles and heat-resistant gloves, and that you're working in a well-ventilated area. Also, ensure you're using the correct soldering equipment and have some experience with soldering techniques.

Materials You Will Need:

- Flexible Neon (12V) with the required connectors

- Soldering iron with a fine-tip soldering station

- Solder wire

- Wire strippers

- Wire Cutters

- Silicone Glue

- Flux (optional, for improved solder flow)

Procedure:

1. Prepare Your Work Area:

- Ensure your work area is clean, well-ventilated, and free from any flammable materials.

- Set up your soldering iron on a heat-resistant surface.

- Put on your safety goggles and heat-resistant gloves.

2. Prepare the Wires:

- Strip the insulation from the ends of the wires you intend to solder. Typically, you'll need to expose about 1/4 inch (6mm) of wire.

- Twist the exposed wire strands together to prevent fraying.

3. Tinning the Wires:

- Heat the soldering iron to the appropriate temperature.

- Apply a small amount of solder to the tip of the soldering iron (this is called tinning).

- Carefully touch the tinned tip of the soldering iron to the exposed wire. The heat will transfer, and the wire should start to melt the solder.

- Apply a little more solder to ensure the wire is fully coated and tinned. This will help with the actual soldering process.

4. Soldering the Connections:

For Single Colour:

- Match the positive and negative wires to their corresponding pads on the Flexible Neon.

- Hold the tinned wire against the pad and apply the soldering iron to the wire and pad simultaneously.

- Allow the solder to melt and flow, creating a secure connection.

- Remove the soldering iron and let the solder cool and solidify. Ensure the wires are held in place until the solder hardens.

- Test the Flexible Neon to ensure it's functioning correctly.

For RGB:

- Solder the positive polarity wire to its respective pad on the Flexible Neon.

- Identify the Red, Green, and Blue terminals for the negative polarity wires.

- Solder each negative wire to its corresponding terminal on the Flexible Neon.

- Make sure the wires are securely attached, and the solder joints are clean.

- Test the Flexible Neon to ensure it's functioning correctly.

For Pixel:

- Solder the positive and negative polarity wires to their respective pads on the Flexible Neon.

- Locate the data signal wire and solder it to the Data pad on the Flexible Neon.

- Ensure that all solder connections are solid and without any short circuits.

- Test the Flexible Neon to ensure it's functioning correctly.

5. Waterproofing and Protecting the Connections:

- Inspect your soldered connections to ensure they are clean and secure.

- Fill exposed pads with silicone glue and slide your desired end cap onto the Flexible Neon.

- This will help retain its IP rating

6. Final Checks:

- Inspect your soldered connections to ensure they are clean and secure.

- Make sure there are no loose wires or exposed connections.

- Test the Flexible Neon to ensure it's functioning correctly.

Remember to exercise caution when working with hot soldering irons, and always follow safety guidelines to prevent burns or other injuries. If you're unsure about any part of the soldering process or need assistance with choosing the right controller, it's advisable to contact Flexible Neon for guidance and support.

Direct Lighting Vs. Indirect Lighting: Illuminating Your Space Right

When it comes to creating the perfect ambience in your living or working spaces, understanding the nuances of lighting is crucial. Two of the most popular lighting schemes, direct lighting and indirect lighting, offer distinct advantages and applications. Before embarking on any lighting project, it's essential to grasp the key differences between them.

Direct Lighting: Focusing the Beam

Direct lighting is all about precision. In this scheme, the light source directs its rays to illuminate a specific area or object. The result is a focused and intense spotlight effect, creating a well-defined hotspot at the centre of attention. Think of the concentrated illumination from a desk lamp, and you have a classic example of direct lighting.

Indirect Lighting: The Art of Diffusion

Conversely, indirect lighting takes a different approach. Here, the light source emits its rays upwards, allowing light to diffuse throughout the space. Rather than concentrating on a particular area, indirect lighting bathes the entire room in a gentle, even glow. It achieves this by reflecting light off surfaces, such as ceilings or walls, before it spreads throughout the space.

Distinguishing Between Direct and Indirect Lighting

Understanding the distinctions between these two lighting schemes is vital. Let's explore the pros and cons of each:

Direct Lighting: Shedding Light on the Benefits

- Focus: Direct lighting excels at focusing on specific objects or areas, making it ideal for tasks and highlighting points of interest.

- Highlight: It creates defined hotspots, making it perfect for showcasing products, exhibits, or architectural details.

- Safety: Direct lighting enhances visibility in potentially hazardous or dimly lit spaces, such as stairs or roads.

- Aesthetic Appeal: When used thoughtfully, direct lighting can provide an aesthetic touch and create captivating shadow effects on walls.

Direct Lighting: Shedding Light on the Drawbacks

- Harsh Shadows: The concentrated light can create harsh shadows, which may not be ideal for all environments.

- Screen Reflection: Direct lighting can cause reflections on screens, potentially affecting visual comfort.

- Glare: It may produce glare, leading to eye strain.

- Uneven Lighting: The ceiling often remains dark as most of the light is directed downward.

Indirect Lighting: Benefits of the Subtle Approach

- Illusion of Spaciousness: Indirect lighting gives the illusion of a larger space by diffusing light evenly without revealing the light source.

- Glare Reduction: It minimises glare and is suitable for rooms with screens, such as those with TVs or computers.

- Soothing Atmosphere: Indirect lighting casts a calming, even light in all directions, creating a relaxed ambience in various settings.

- Structural Accentuation: It's excellent for accentuating unique structures in both interior and exterior spaces.

Indirect Lighting: Consider the Drawbacks

- Brightness: Indirect lighting may not provide enough illumination on its own and may need supplemental lighting.

- Dark Spaces: Over-reliance on ceiling-based indirect lighting can leave some areas of a room in relative darkness.

- Limited Visibility: In some cases, it may not offer sufficient visibility, particularly in workspaces.

When to Use Direct and Indirect Lighting

The choice between direct and indirect lighting largely depends on the purpose of the lighting and the space in question:

Direct Lighting - Ideal For:

- Home & Office: Direct lighting enhances workspaces, such as desks and conference tables.

- Work/Study Table: Table lamps offer focused illumination for reading or working.

- Kitchen: Ideal for task lighting over workstations and sinks.

- Museum & Art Gallery: Perfect for highlighting specific exhibits or artworks.

- Street Lights: Ensures safety by illuminating specific areas at night.

- Decoration: Direct lighting can serve as both functional lighting and decor.

Indirect Lighting - Ideal For:

- Ceiling & Wall Lighting: Creates a modern, ambient atmosphere.

- Kitchen Cabinet: Adds a touch of elegance and practicality.

- Bathroom: Enhances the overall look while ensuring practicality.

- Automobiles & Marines: Used for decoration and accent lighting.

- Hotel & Restaurants: Elevates interior and exterior aesthetics.

- Architectural Designs: Highlights architectural elements.

Combining Direct and Indirect Lighting

To achieve the best of both worlds, you can combine direct and indirect lighting in your space. For instance, use indirect lighting to create a warm, ambient atmosphere throughout the room, and then employ direct lighting to focus on specific tasks or areas.

Direct Lighting Vs. Indirect Lighting: The Verdict

While both direct and indirect lighting have their merits, indirect lighting often shines as the preferred choice for its even and elegant illumination. It reduces glare, provides superior visibility, and contributes to a modern aesthetic. In contrast, direct lighting can be ideal for spotlighting specific areas or objects but comes with limitations like harsh shadows and uneven lighting. Ultimately, the choice between these two lighting schemes depends on your specific needs and the desired ambience.

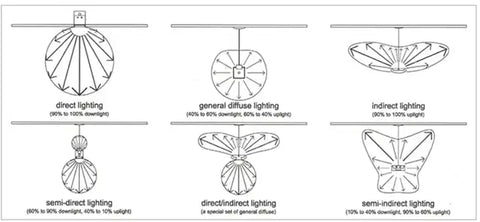

Types of Lighting Schemes:

Lighting schemes are categorised into five types:

- Direct Lighting: Approximately 90% of the light is directed downwards, with some reflected upwards.

- Semi-Direct Lighting: Typically, 60% to 90% of the light is directed downward, with the remainder reflected upwards.

- Indirect Lighting: Around 90% of the light is emitted upwards, with some reflected downwards.

- Semi-Indirect Lighting: Similar to semi-direct lighting but with the distribution of light in the opposite direction.

- General Lighting: Light is evenly distributed in all directions, creating a soft, ambient illumination.

Understanding these lighting schemes can help you make informed decisions when designing the lighting for your space. Whether you prefer the precision of direct lighting or the elegance of indirect lighting, choosing the right lighting scheme can transform any room into a comfortable and functional environment.

Choosing the Right LED Flexible Neon for Your Lighting Project

When selecting an LED neon flex for your lighting project, several key factors must be considered to ensure it meets your specific needs. Here are the essential considerations:

1. Brightness: Determine the desired brightness by checking the lumen rating in the specifications. Higher lumen ratings indicate a brighter output. Flexible Neon employs high-quality SMD technology to ensure a consistently bright display. When choosing brightness levels within our range of neon, use the wattage as an indicator (higher wattage = brighter).

2. Waterproofing: For outdoor use, it's crucial to select a waterproof LED neon flex. Check the Ingress Protection (IP) rating, with IP67 or IP68 being ideal for water-resistant lighting.

3. Colour: Our range of Flexible Neon (12V) offer a wide range of colour options, including Emerald Green, Fire Truck Red, Hot Pink, Rose Pink, Light Pink, Icy Blue, Mars Green, Warm White 3000K, Neutral White 4000K, Pure White 6000K, Pixel, RGB, Royal Blue, Sun Yellow, Tangerine Orange. Our pixel neon allow you to control the colour pattern of specific sections, enabling dynamic lighting effects. Whereas RGB allows you to control throughout the colour wheel and through basic modes that the whole strip adheres to.

4. Dimension: The size and shape of the LED neon flex can impact its lighting output. A thicker and wider flex will provide more prominent illumination. Choose the dimension that aligns with your lighting requirements.

5. Shape: LED neon flexes come in various shapes, such as flat, slim, mushroom, semicircle, mini, and more. Each shape creates different lighting effects, so select one that suits your design objectives.

6. CRI (Colour Rendering Index): For applications where colour accuracy is crucial, consider the CRI rating. A CRI rating above 80 ensures high-quality colour representation.

7. Bend Type: Different LED neon flexes offer various bending options, including horizontal and vertical. Select the bending type that aligns with your design needs. Horizontal bending is particularly well-suited for creating signs and other designs where the neon flex needs to follow a specific shape or contour. This bending option allows for precise shaping, ensuring that your neon sign or lighting element accurately represents your intended design. Whether it's a logo, text, or any custom shape, horizontal bending provides the flexibility needed to bring your creative vision to life. Vertical bending, refers to the bending of the flexible neon strip in a vertical direction. This bending style allows you to create designs or lighting elements where the neon flex extends vertically or up and down.

8. Price: LED neon flex prices vary based on factors like structure, colour, and bending type. We at Flexible Neon try to keep our prices as affordable, to encourage a brighter and fun world.

9. Warranty: Pay close attention to warranty policies, especially for outdoor installations, where the neon must withstand harsh weather conditions. Our range of silicone is best suited for the outdoors due to its better UV rating.

How to Make a DIY Flexible Neon Sign

What Are Flexible Neon Signs?

Neon signs, reimagined with silicone rather than the traditional glass tubes filled with volatile gases, represent a contemporary shift in lighting technology. Unlike the outdated and potentially hazardous gas-filled methods, our silicone or PVC based neon signs offer a safer, more versatile, and energy-efficient solution. These signs harness the power of modern LED technology to deliver vibrant and customisable illumination, making them perfect for a wide array of applications, from signage to decorative lighting. They are suitable for outdoor advertisements and can also be used to decorate homes, offices, restaurants, and more.

How Do Flexible Neon Signs Work?

Silicone and PVC neon flex lights differ from traditional glass-tube neon signs. These contemporary alternatives use flexible materials and incorporate LED components for illumination. Inside these neon flex lights are LED's, which emit light when an electrical current passes through them. The specific materials and LED designs determine the light's colour, offering a wide range of customisation. These lights are flexible, durable, and energy-efficient due to LED technology, making them ideal for various applications, from signage to decorative lighting

Colours of Flexible Neon Signs

Our Flexible Neon colour range includes Emerald Green, Fire Truck Red, Hot Pink, Rose Pink, Light Pink, Icy Blue, Mars Green, Warm White 3000K, Neutral White 4000K, Pure White 6000K, Pixel, RGB, Royal Blue, Sun Yellow, and Tangerine Orange.

What Are Flexible Neon Signs?

Flexible Neon signs are an affordable alternative to traditional, costly neon signage. They are made using PVC or silicone-wrapped flexible linear SMD LED strips, known as Flexible Neon lights. These Flexible Neon is safer, more durable, and more cost-effective than traditional neon signs. Therefore, Flexible Neon lights are an excellent choice for creating DIY Flexible Neon signs.

How to Make Your Own Flexible Neon Sign

You can create your own Flexible Neon sign without professional assistance. It's a fun and creative project that you can accomplish with a few pieces of equipment and following some straightforward steps. Here's how you can design and craft your own Flexible Neon sign:

What Do You Need to Make a Flexible Neon Sign?

Before you embark on creating your Flexible Neon sign, gather the necessary materials and tools. Here's a list of what you'll need:

- Paper and pencil

- A surface to mount your sign on (we recommend black)

- Flexible mounting channel

- Screws

- Spray paint

- LED Neon flex lights in your desired colour and size

- Quick Connectors (if needed)

- Cutters suitable for Flexible Neon (42mm)

- Soldering Iron

- Wires (appropriate gauge)

- Hot glue gun

With these materials at hand, you're ready to bring your DIY Flexible Neon sign to life. Follow the subsequent steps to craft your personalised Flexible Neon sign.

Designing and Crafting Your DIY LED Neon Sign:

Follow along with our how-to video with one of our talented Flexible Neon team member on YOUTUBE

Now that you have gathered all the necessary materials, follow these detailed steps to create your personalised Flexible Neon sign:

Step 1: Design Your Sign

1.1. Begin by sketching your desired design for the Flexible Neon sign on a piece of paper. This will serve as your blueprint.

1.2. Pay close attention to the size and shape of your sign, as this will determine the length of Flexible Neon required.

Step 2: Prepare Your Mounting Surface

2.1. Choose a suitable surface to mount your Flexible Neon sign. It could be a wall, a wooden board, or any other flat surface.

2.2. If needed, paint or decorate the surface to enhance the visual appeal of your sign.

2.3. Spray paint your Flexible Channel to the colour of the surface.

Step 3: Secure the Flexible Mounting Channel

3.1. Attach the flexible mounting channel to your prepared surface. Use screws to secure it firmly in place.

3.2. Ensure that the mounting channel follows the shape and dimensions of your sign design.

Step 4: Measure and Cut the Flexible Neon

4.1. Measure the length of LED neon flex lights required for your design, following the outline of your sketch.

4.2. Use cutters suitable for Flexible Neon to trim the LED neon flex lights to the precise length needed.

Step 5: Wiring and Connection (please see our wiring guide for further details)

5.1. Examine the Flexible Neon lights and identify the input and output ends.

5.2. Using appropriate wires and a soldering iron, connect the input end of the Flexible Neon to the power source. Be sure to connect the right polarities, and to follow the manufacturer's instructions for wiring.

5.3. Secure the wires and connections to prevent any loose or exposed components. We recommend using silicone glue and end caps to protect the LED's.

5.4. Test the connection to ensure the Flexible Neon lights illuminate correctly.

Step 6: Install the Flexible Neon

6.1. Carefully insert the Flexible Neon into the flexible mounting channel, following the shape of your design.

6.2. Secure the Flexible Neon in place within the channel, ensuring they remain evenly spaced and aligned. Some silicone glue may be used for extra adhesion.

Step 7: Final Touches

7.1. Inspect the Flexible Neon for any loose components, exposed wires, or irregularities.

7.2. If necessary, use a hot glue gun to secure any loose parts and ensure a tidy appearance.

7.3. Make any final adjustments to the positioning of the Flexible Neon.

Step 8: Power Up Your DIY LED Neon Sign

8.1. Connect the Meanwell LED Driver to the Flexible Neon sign.

8.2. Turn on the power and enjoy the vibrant glow of your personalised Flexible Neon sign.

Tips and Precautions:

-

Safety First: When working with electrical components, prioritise safety. Ensure the power source is disconnected while making connections, and only turn it on once everything is securely in place.

-

Precision Matters: Measure and cut the Flexible Neon accurately to match your design. Precise cutting will ensure a professional-looking finished product.

-

Proper Wiring: Follow the manufacturer's guidelines for wiring and connections to prevent any electrical issues or damage to the Flexible Neon.

-

Securely Mount: Ensure the flexible mounting channel is firmly attached to the chosen surface to support the weight of the Flexible Neon.

-

Test Before Finalising: Before securing all components permanently, test the Flexible Neon sign to confirm that it functions correctly.

-

Creative Freedom: Don't hesitate to experiment with different colours and designs to achieve your desired aesthetic.

Creating your DIY Flexible Neon sign can be a rewarding and visually striking project. With attention to detail and safety precautions, you can craft a personalised piece of illuminated art to enhance your space or promote your message. Enjoy the vibrant glow of your unique creation!

Choosing the Right Wire Gauge for Flexible Neon Lighting Applications

Choosing the correct wire gauge for flexible neon lighting is essential for safety and efficiency. It is important to consider the current load and voltage drop to achieve optimal performance. Various American Wire Gauge (AWG) options are available to meet the specific needs of different lighting applications.

Understanding the Longevity of Flexible Neon LED Strip Lights

LED strip lights, like those offered by Flexible Neon, are renowned for their longevity and versatility. To understand how long these LED strip lights can last, it's essential to examine their structure and the factors that influence their lifespan.

The Structure of LED Strip Lights:

The main components of LED strips include LED's (Light Emitting Diodes), FPCB (Flexible Printed Circuit Boards), resistors, and other essential elements. These components are assembled using Surface Mount Technology (SMT) Assembly Process, which mounts LED's, resistors, and other components onto the FPCB.

Some outdoor or underwater LED strips may also have a protective silicone or PU glue coating. However, it's crucial to note that LED strips with higher IP ratings, designed for enhanced protection against dust and water, may have a somewhat shorter lifespan compared to IP20-rated LED strips. This is primarily because LED strips with higher IP ratings struggle to dissipate heat as efficiently. Generally, cooler environments support a longer LED lifespan, as higher temperatures tend to reduce light output. (For more details on how heat affects LED's, see "How are LED's affected by heat?")

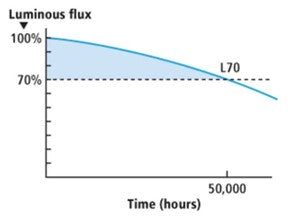

Understanding LED Lifetime and the "L70" Rule:

Unlike traditional incandescent or fluorescent bulbs that fail abruptly, LED's gradually lose their light output over time. They continue working until they become too dim to be practical. The industry has established a standard for this gradual decrease in light output, known as the "L70" metric. It signifies the point at which an LED has dimmed to 70% of its original brightness.

In some instances, you may come across symbols like "LxByCz(h)" to describe the lifetime of LED luminaires. Here's what it means:

- "Lx" denotes the number of hours after which the luminous flux has dropped to x percent.

- "By" signifies the percentage of luminaires in the same group that have fallen below the specified luminous flux.

- "Cz" indicates the percentage of luminaires in the group that have experienced total LED failure.

For example, "L70B10C0.1 (50,000 h)" means that after 50,000 hours:

- The LED luminaires must still provide at least 70% of their initial luminous flux.

- Up to 10% of the luminaires can provide less than 70% of the initial luminous flux.

- In just 0.1% of the luminaires, all LED's may have failed.

How Is "L70" Calculated?

To calculate LED lifetime, a testing method called LM-80 is often employed. This method specifies a predetermined temperature and driving current for testing LED samples. The light output change is measured at intervals of 1000 hours, up to a maximum of 10,000 hours. Reputable manufacturers conduct LM-80 testing at third-party laboratories to ensure impartial results. They then publish these results in report format. It's important to note that reliable LED strip suppliers should be able to provide LM80 test reports, especially when purchasing large quantities.

However, LED life testing can be time-consuming. For instance, even with LED's operating 24/7, a 10,000-hour test takes around 14 months. This timeframe is impractical for fast-moving industries like LED lighting. To address this issue, the TM-21 extrapolation algorithm is employed. It considers the performance of LM-80-tested samples during the first few thousand hours and provides an estimated lifetime.

Factors Affecting LED Strip Light Lifespan:

Several factors can affect the lifespan of LED strip lights:

-

FPCB (Flexible Printed Circuit Board): High-quality, double-layer pure copper flexible PCBs facilitate the smooth passage of significant current, reduce heat generation, and promote efficient heat dissipation. By attaching the LED strip to an aluminium profile, you can dissipate heat effectively and lower the operating temperature, thus extending LED life.

-

Double-Sided Tape: Quality matters when it comes to adhesive tape. LED strip lights from reputable suppliers often use high-quality tapes, like the 3M brand VHB tape. Proper tape quality ensures long-lasting installations and good thermal conductivity.

-

Resistors: Resistors regulate the forward current through LED's to maintain their designed brightness. It's crucial to use high-quality resistors from reputable manufacturers to avoid shortening the LED strip's life or causing damage.

-

Power Supply: The power supply is a critical component. Always use a reliable, brand-name power supply to ensure stable voltage output. Low-quality power supplies can deliver unstable voltages that might exceed the LED strip's working voltage, potentially damaging it.

-

Heat Dissipation: Heat can significantly reduce LED lifespan. To manage heat effectively, install LED strips in well-ventilated areas. If feasible, attach the LED strip to an aluminium profile to aid in heat dissipation, as aluminium is an excellent conductor of heat.

By considering these factors and following best practices for installation and maintenance, you can maximise the lifespan of your Flexible Neon LED strip lights, ensuring they provide brilliant and reliable illumination for years to come.

Connecting Wires Using Soldering and WAGO Connectors with Polarity Match

Whether you're working on electrical projects or crafting intricate setups, knowing how to properly connect wires is essential for safety and efficiency. In this detailed guide, we'll walk you through two common methods: soldering and using Wago connectors. We'll also emphasise the importance of maintaining consistent wire polarity to ensure your connections work seamlessly.

Materials You'll Need:

- Wires to be connected

- Soldering iron and solder (if soldering)

- Wago connectors (if using)

- Wire stripper or cutter

- Dual Adhesive Heat shrink tubing (if soldering)

- Electrical tape (if using)

- Multimeter (for polarity verification)

Method 1: Soldering Wires

Step 1: Prepare the Wires

- Strip about 1 cm of insulation from each wire using a wire stripper.

- Twist the exposed wire strands to prevent fraying.

- For safety, we recommend the wires are feathered to ensure the opposing wires do not touch.

Step 2: Solder the Wires

- Heat your soldering iron and apply a small amount of solder to the tip.

- Hold the wires together with their stripped ends aligned.

- Touch the soldering iron's tip to the wires, allowing the heat to melt the solder and create a strong bond between the wires.

Step 3: Insulate with Heat Shrink Tubing (This step can be done before step 2 to make a more streamlined connection)

- Slide a piece of heat shrink tubing over the soldered area.

- Use a heat gun to shrink the tubing, providing insulation and protection to the solder joint.

Method 2: Using Wago Connectors

Step 1: Prepare the Wires

- Strip about 1 cm of insulation from each wire.

- Insert the stripped wires into the appropriate Wago connector slots (same polarities). Ensure each wire is securely inserted.

Step 2: Secure the Wires

- Press down on the orange lever of the Wago connector. This will securely clamp the wires in place.

Step 3: Verify Polarity

- Use a multimeter to verify that the wire polarity is consistent between the connections.

- Connect the multimeter probes to the corresponding wires to ensure positive (+) and negative (-) match.

General Tips:

- Weatherproofing: Employing electrical tape is an effective method for swiftly safeguarding your connection against environmental factors. Exercise caution, as any openings can pose potential hazards.

-

Maintain Consistent Polarity: To prevent electrical issues, ensure that the wires' polarity (positive and negative) matches correctly when connecting them. A reversed polarity can lead to equipment damage or malfunction.

-

Safety First: Always work in a well-ventilated area, and take necessary precautions to avoid burns when soldering. If using Wago connectors, handle them carefully to prevent any accidental damage.

-

Practice Good Wire Management: Keep the wire connections tidy by using cable ties, conduit, or other wire management solutions.

-

Test Your Connections: Before finalising your project, test the connected wires using appropriate electrical equipment to verify that the connections are functioning as intended.

-

Wear Safety Gear: When soldering, protect your hands with gloves and your eyes with safety goggles to prevent accidental burns or splashes.

By following this guide, you'll be able to confidently and safely connect wires using both soldering and Wago connectors while maintaining proper polarity. This skill will prove invaluable for a wide range of electrical and DIY projects.

Creating an LED Sign or Feature Using Flexible Neon Accessories

Flexible Neon lighting offers a versatile and captivating way to create stunning LED signs and features that draw attention and enhance the ambience of any space. With a wide range of neon sizes and complementary accessories, you can let your creativity shine and design captivating displays. Follow this detailed guide to harness the full potential of Flexible Neon accessories for crafting your own LED masterpiece.

Step 1: Choose Your Neon Size

Flexible Neon comes in various sizes, allowing you to customise your LED sign or feature according to your design and space requirements. Available sizes include:

- 6x12mm

- 8x16mm

- 8x10x16mm

- 10x13x22mm

- 13x15mm

Step 2: Plan Your Design

Decide on the layout, text, or pattern you want to create with your Flexible Neon LED sign. Take measurements of the area where you plan to install the sign to ensure the neon size fits perfectly.

Step 3: Gather Your Accessories

Flexible Neon accessories play a crucial role in achieving a professional and secure installation. Here's a breakdown of available accessories and their uses:

End Caps: Seal the ends of your Flexible Neon for protection and a clean finish. Available in various styles including regular, end cap with hole, side entry, and low entry.

Mounting Clips: Choose from stainless steel, aluminium, and plastic mounting clips to securely attach the neon to different surfaces. Available in various sizes to match your neon dimensions.

Mounting Channels: Aluminium and stainless steel mounting channels provide a secure and polished way to hold your neon in place. These channels can be bent to fit curved or straight surfaces. The flexible channel is a great way to hold the neon in place around curves and can be easily spray-painted to blend in with your amazing design.

Quick Connectors: Solderless connectors simplify the installation process by allowing you to easily connect neon segments without complex wiring.

Snap Connectors: Solderless connectors to simplify joining two separate pieces of neon together easily and quickly.

End Caps: Waterproof your design with end caps, using silicone glue to hold them in place. Even choose from ones with entry holes in almost every direction.

Coloured End Caps: Enhance the visual impact of your LED sign by using coloured end caps that match or contrast with your neon.

Step 4: Installation Follow these steps to assemble and install your LED sign or feature:

a. Assemble Neon: Using the quick connectors, join the individual neon segments together to form your desired design. Ensure the connections are secure.

b. Attach Mounting Clips: Depending on your surface, attach the appropriate mounting clips to the neon using adhesive or screws.

c. Insert Neon into Mounting Channels: For a more polished look, slide the neon into the aluminium or stainless steel mounting clips/channels, bending them as needed to match your design.

d. Install End Caps: Seal the ends of the neon with end caps using adhesive to maintain the IP rating.

Step 5: Powering Up

Connect the neon to an appropriate power source using trusted 12V LED drivers. Ensure you follow safety guidelines and adhere to electrical regulations during this step.

Step 6: Test and Adjust

Before finalising the installation, test the LED sign to ensure all neon segments are illuminated correctly. Make any necessary adjustments to positioning, angles, or connections.

Step 7: Secure and Enjoy

Once you're satisfied with the installation, secure all components in place and enjoy your custom LED sign or feature. Whether indoors or outdoors, your creation will captivate and illuminate its surroundings.

By utilising the wide array of Flexible Neon accessories and sizes, you can bring your creative visions to life, crafting unique and captivating LED signs and features that leave a lasting impression. Experiment with different combinations to achieve the desired aesthetics and lighting effects for your space.

Why We Prefer Warm White

At Flexible Neon, we prefer warm white lighting for several compelling reasons. Warm white light offers a softer, more natural glow that closely resembles traditional incandescent lighting, creating a welcoming and cosy ambience in any space. Here are some key reasons why warm white is our top choice:

-

Comfort and Relaxation: Warm white light has a colour temperature typically ranging from 2700K to 3500K, which emits a gentle, calming glow that promotes relaxation. It's ideal for areas where people gather, such as living rooms, bedrooms, and dining spaces.

-

Enhancing Decor: Warm white light complements various interior designs and colour schemes, enhancing the aesthetic appeal of your space. It creates a harmonious atmosphere that suits both modern and classic settings.

-

Aesthetic Appeal: Warm white light is often preferred for its flattering effect on skin tones, making it an excellent choice for retail and hospitality spaces, as well as photography studios.

-

Cosy Ambience: Whether it's in a restaurant, café, or residential setting, warm white lighting helps to create a cosy and inviting environment that encourages social interaction and relaxation.

-

Versatility: Warm white lighting is incredibly versatile and can be used in various applications, such as accent lighting, cove lighting, or general room illumination.

-

Well-Being: Warm white light has been associated with improved mood and overall well-being. It is considered more soothing and less disruptive to circadian rhythms than cool white or daylight lighting.

-

Subtle and Stylish: Warm white light adds a touch of elegance and sophistication to any space, making it an excellent choice for creating a warm and inviting atmosphere.

At Flexible Neon, we prioritise the well-being and satisfaction of our customers. We believe that warm white lighting enhances the overall experience and comfort in any environment, making it a preferred option for a wide range of lighting projects. With our extensive collection of warm white LED products, we are committed to helping you achieve the perfect lighting solution that meets your specific needs and preferences.

What is IP Rating

- FAQs

- Gallery

- Contact Us

- T&Cs

- Delivery

- International Shipping

- Refunds Policy

- Privacy Policy

- Buy now

- Guides

Sign up to get the latest on sales, new releases and more…

© 2026 Flexible Neon.